Torque sensors - What are they and what are they used for?

by Quotebeam Team

Jan 23, 2024

In this exploration of torque sensors, we dive into their critical role within manufacturing and automation. Torque sensors, or torque transducers, are specialized devices crucial for measuring rotational force. This blog goes into their definition, operational mechanisms, applications in torque measuring, and the distinct types available in the market.

What is a torque sensor?

Torque sensors, often referred to as torque transducers or torque meters, stand out as precision instruments meticulously crafted to measure the rotational force exerted on an object. Their significance extends across diverse industries, playing an indispensable role in ensuring precise torque monitoring and control. These instruments contribute invaluable, accurate data, facilitating the optimization of manufacturing processes and the enhancement of overall efficiency. The reliability of torque sensors solidifies their position as essential tools, acting as the backbone for maintaining precision and control in the dynamic landscape of industrial applications.

How torque sensor works?

Torque sensors work by using something called strain gauges. Picture a strain gauge like a tiny, sensitive ribbon. When the toy top spins or twists, it puts a little pressure on the ribbon, making it slightly stretch or deform. The torque sensor is like a super smart detective that can notice these tiny changes.

Now, when the ribbon stretches or deforms, it sends an electrical signal to the torque sensor that tells it how much the top is spinning or twisting. The torque sensor then translates this message into something we can understand, like telling us exactly how fast the top is spinning.

How are torque sensors used in torque measuring?

Torque sensors play a pivotal role in torque measuring by accurately assessing the rotational force or twisting applied to objects. Here's how they contribute to this essential aspect of industrial processes:

- Precision Measurement: Torque sensors utilize specialized mechanisms, such as strain gauges, to precisely detect even the slightest changes in shape caused by torque. This allows for highly accurate measurements of rotational force.

- Real-time Monitoring: In manufacturing processes, torque sensors enable real-time monitoring of torque levels. This is crucial for ensuring that machinery operates within specified torque limits, preventing over-tightening or under-tightening of components.

- Quality Control: Torque sensors are employed in quality control procedures to verify the accuracy of torque application. This is particularly important in industries where the proper torque is critical for the functionality and safety of products.

- Bolt Tightening Applications: In assembly lines and construction, torque sensors are frequently used to monitor and control the torque applied during bolt tightening. This ensures that bolts are securely fastened without the risk of damage due to excessive force.

- Motor Performance Optimization: Torque sensors contribute to optimizing the performance of motors by precisely measuring the torque generated during operation. This information is valuable for adjusting motor parameters to achieve optimal efficiency.

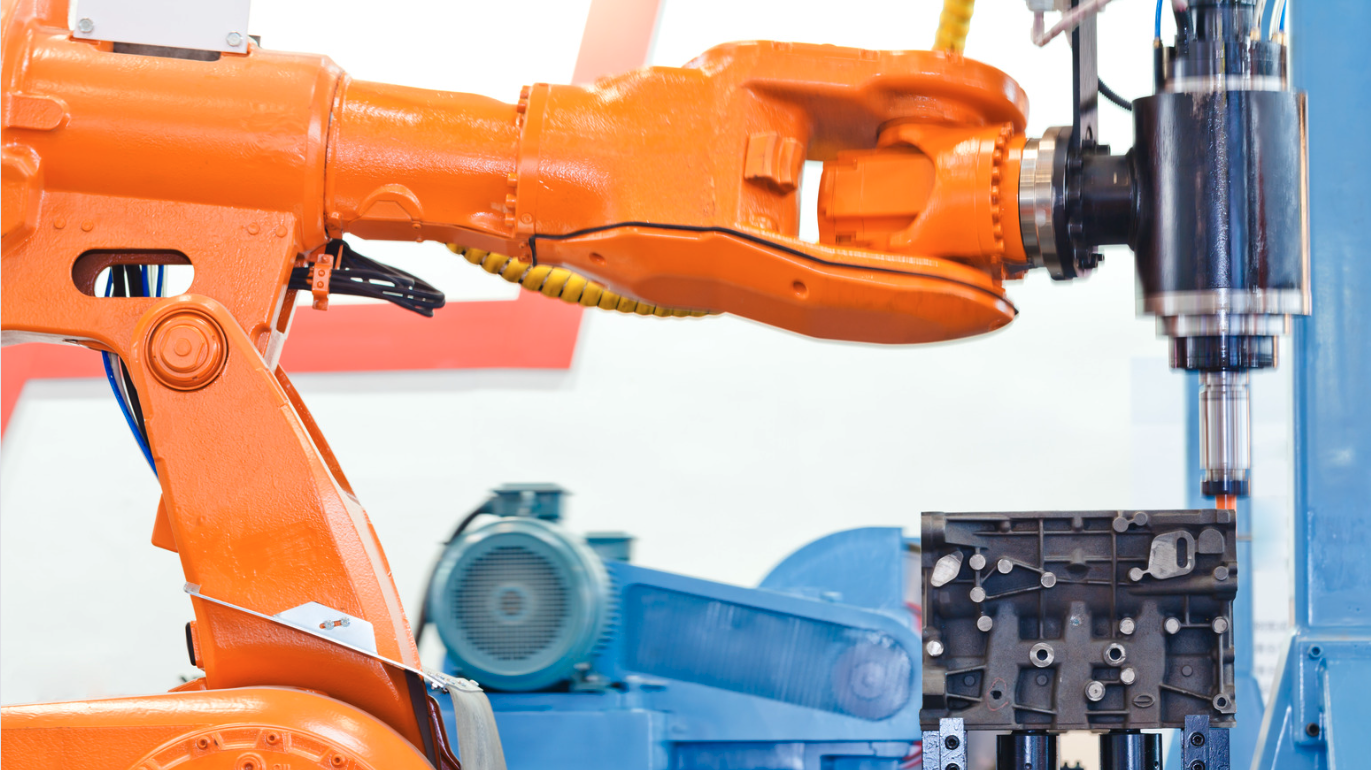

- Robotic Applications: In robotics, torque sensors are integrated into joints and actuators to measure the torque exerted by robotic arms. This capability enhances the precision and control of robotic movements, ensuring smooth and accurate operations.

- Aerospace Industry: Torque sensors find applications in the aerospace industry, where the accurate measurement of torque is crucial for the performance and safety of aircraft components subjected to varying torque loads.

What are the types of torque sensors?

Understanding the specific types will help you choose the right sensor for your needs:

- Reaction Torque Sensors:

- Measure torque by reacting to applied force, offering reliable output.

- Rotary Torque Sensors:

- Utilize a rotating shaft for torque measurement, ideal for rotating components.

- Magnetoelastic Torque Sensors:

- Rely on magnetic property changes for torque measurement, providing non-contact and reliable solutions.

- Static Torque Sensors:

- Stable for constant torque applications, ensuring precision.

- Dynamic Torque Sensors:

- Suited for dynamic applications with varying torque, delivering accuracy in changing conditions.

By understanding the various types of torque sensors, you can make informed choices to enhance efficiency and precision in industrial processes. Delving into the intricacies of these devices reveals their crucial role in manufacturing and automation, contributing to precision, reliability, and overall efficiency.