Everything about Stepper Motors: Definition, Types and Uses

by Quotebeam Team

Feb 26, 2024

Stepper motors play a crucial role in various industries, offering precise control and positioning capabilities. In this comprehensive guide, we'll delve into what stepper motors are, how they work, their types, applications, and the key differences between stepper and servo motors

What is a stepper motor?

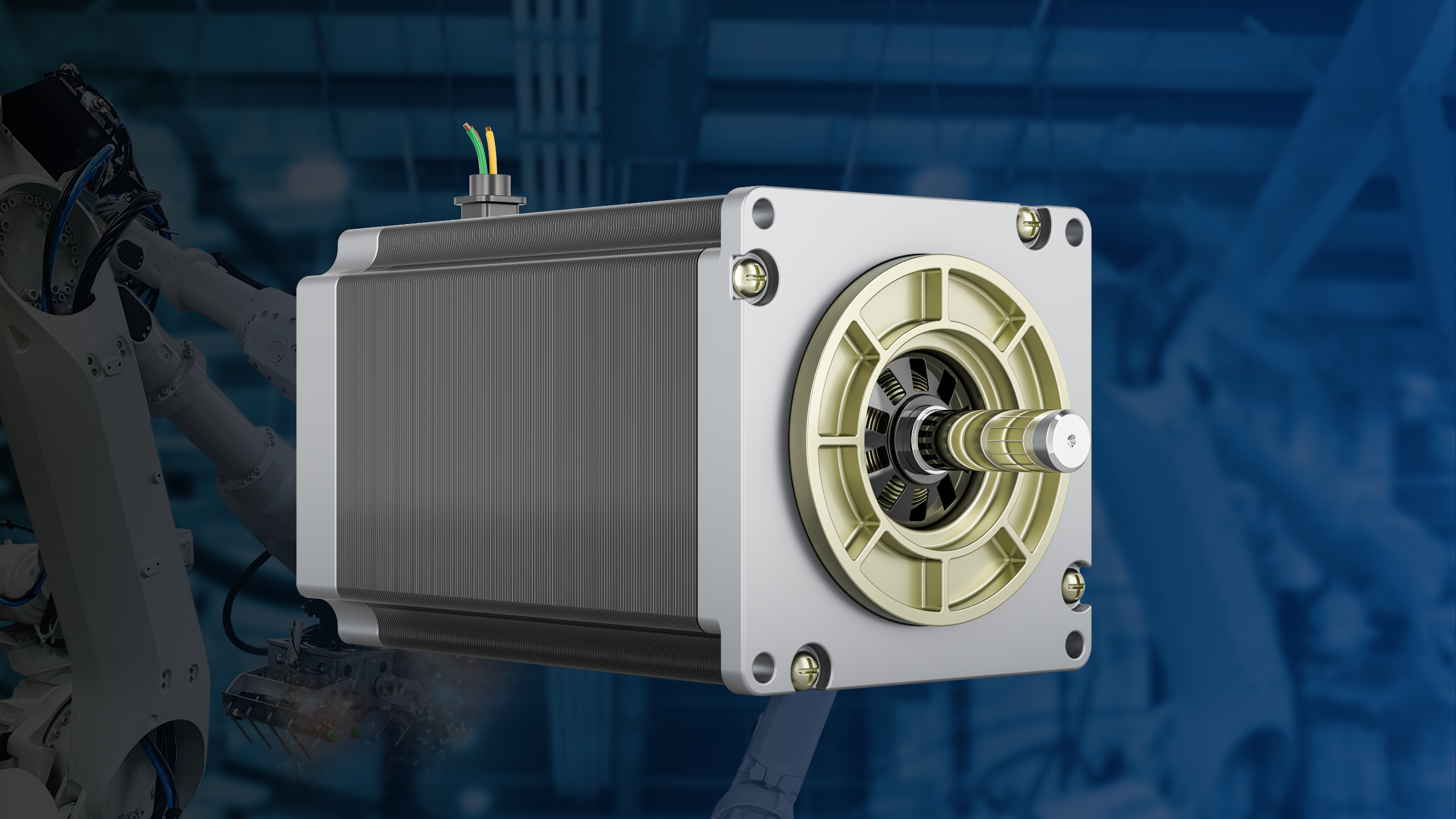

A stepper motor is a brushless DC electric motor that divides a full rotation into several equal steps. These motors provide precise control over angular position without the need for feedback mechanisms. Stepper motors are widely used in automation, robotics, 3D printers, CNC machines, and more.

How do stepper motors work?

Stepper motors work by converting digital pulses into precise mechanical motion. Each pulse rotates the motor by a fixed angle, known as a step. By controlling the sequence and timing of these pulses, stepper motors can achieve accurate positioning and rotation. This makes them ideal for applications requiring precise control, such as in CNC machines and 3D printers.

What are stepper motors used for?

Stepper motors find applications in various industries, where their precise control and reliability are indispensable. Let's explore how different sectors utilize stepper motors:

- Industrial Automation:

- In factories and production lines, stepper motors play a critical role:

- Robotic Arms: These motors are essential for assembling products with precision.

- Conveyor Systems: Stepper motors ensure accurate movement along production lines, facilitating efficient manufacturing processes.

- In factories and production lines, stepper motors play a critical role:

- Robotics:

- Across industries, stepper motors are vital components in robotic systems:

- Robotic Welding Arms: Ensuring precise movement for consistent weld quality in manufacturing.

- Warehouse Robots: Stepper motors enable accurate picking and placing of items in logistics operations.

- Across industries, stepper motors are vital components in robotic systems:

- Medical Devices:

- In the medical field, stepper motors are integral to various equipment:

- Imaging Devices: These motors ensure precise positioning for clear and accurate medical images.

- Surgical Robots: Stepper motors assist surgeons in performing minimally invasive procedures with precision and control.

- In the medical field, stepper motors are integral to various equipment:

- Consumer Electronics:

- Stepper motors enhance the functionality of many consumer products:

- Cameras: Enabling autofocus mechanisms for sharp and clear photos.

- 3D Printers: Controlling the movement of the print head and platform to achieve accurate prints.

- Stepper motors enhance the functionality of many consumer products:

- Telescope Mounts:

- For astronomy enthusiasts and professionals, stepper motors are essential components:

- Tracking Systems: These motors allow telescopes to track celestial objects accurately, facilitating clear observations and astrophotography.

- For astronomy enthusiasts and professionals, stepper motors are essential components:

Stepper motors play a vital role across diverse industries, enabling precise control and automation in various technological applications.

What are the types of stepper motors?

Stepper motors come in several types, each suited for different applications. The most common types include:

- Permanent Magnet (PM) Stepper Motors: These motors have a permanent magnet rotor and are known for their low cost and simplicity.

- Hybrid Stepper Motors: Combining the features of PM and VR stepper motors, hybrids offer improved performance and torque.

- Variable Reluctance (VR) Stepper Motors: VR stepper motors use a soft iron rotor and are popular for their high-speed capabilities and low cost.

Understanding the differences between these types can help in selecting the right stepper motor for specific applications.

What is the difference between stepper motors and servo motors?

Stepper motors and servo motors are both used for precise motion control, but they operate differently and have distinct characteristics. While stepper motors move in discrete steps, servo motors operate continuously and rely on feedback mechanisms for precise positioning. Stepper motors are simpler to control and are cost-effective for many applications, while servo motors offer higher speed, accuracy, and torque.

To recap, stepper motors are versatile devices with a wide range of applications across various industries. Understanding their operation, types, and differences from servo motors can help in choosing the right motor for specific automation needs. Whether in manufacturing, robotics, or consumer electronics, stepper motors continue to drive innovation and efficiency in modern technology.